At present, Global aluminum alloy industry pattern competition over overcapacity in the global aluminum alloy industry is intensifying. The problem of overcapacity in the aluminum industry has become a common problem in the development of the global aluminum industry.

The upstream, midstream and downstream industrial chains of the aluminum industry chain can be regard as six links, including bauxite mining, alumina refining, aluminum metal smelting, aluminum alloy production, aluminum processing and end product manufacturing.

The industry chain is obvious for single production raw material and a single production process. Bauxite is almost the only raw material for the production of alumina. The Bayer process produces more than 90% of the world’s alumina ourput , and all primary aluminum uses the molten salt electrolysis process. Global alumina production capacity is mainly in countries such as China, Australia, Brazil and India.

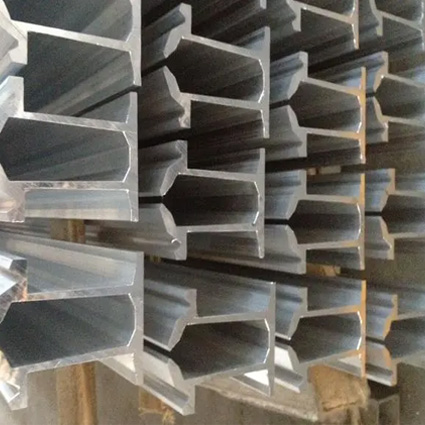

Aluminum are widely-using in various fields, especially in the construction industry, transportation industry and packaging industry. In the construction industry, aluminum alloy is raw material of aluminum alloy doors and windows. As well as in aluminum-plastic pipes, decorative panels, aluminum panel curtain walls, etc. In the transportation industry, the Al-alloy are vital components and decorative parts of motorcycles, cars, trains, subways, airplanes, ships. In the packaging industry, aluminum alloys are suitable for various types of flexible packaging, cans, bottle caps, etc.

Silicon Metal and Magnesium Metal are both important raw materials in the Al-Alloy industry. Si Metal and Magnesium Ingot are also the most common alloy additives in the aluminum alloy industry.

To sum up, the global aluminum alloy industry pattern built a certain scale and basic characteristics. The upper, middle and lower reaches of the aluminum industry chain are interrelated. Al alloys are vital in the construction industry, transportation industry, packaging industry and other fields.