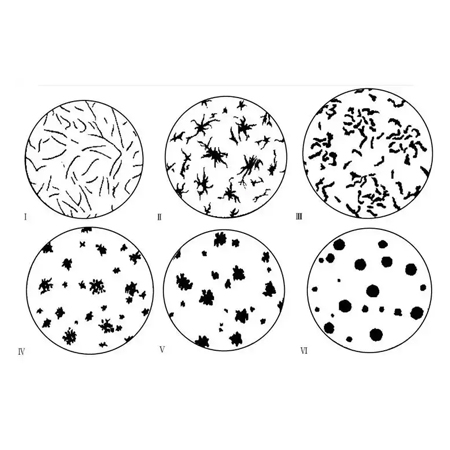

Carbon in cast iron exists primarily in two forms: cementite and graphite. Cementite, a compound of carbon and iron, increases cast iron’s hardness but reduces its toughness, making it more susceptible to brittle cracking. Graphite, on the other hand, enhances cast iron’s lubricity and vibration damping, improving machinability and thermal conductivity. Different forms of graphite directly affect cast iron’s mechanical properties and usability:

A-C Forms of Graphite in Cast Iron

Type A graphite forms when eutectic transformation occurs under conditions of strong graphite nucleation, low cooling rate, and minimal undercooling. Observed under an optical microscope, graphite appears as uniformly distributed, non-directional, curved flakes. Their length varies depending on the nucleation conditions and cooling rate. High-quality structural castings ideally require medium-length Type A graphite.

Type B graphite appears chrysanthemum-shaped under an optical microscope, with finer graphite flakes in the center of the eutectic and coarser flakes at the periphery. In reality, the center is Type D graphite, while the periphery is Type A graphite. Type B graphite nucleation conditions are poorer than those of type A graphite. And the undercooling during the eutectic transition is also greater than that required for type A graphite formation. During crystallization, undercooled graphite (type D) first forms in the center of the eutectic. The released latent heat of crystallization reduces the undercooling of the surrounding area, resulting in the formation of type A graphite. If type B graphite exists in small quantities, it has little impact on the properties of cast iron.

Type C graphite primarily occurs in cast iron with a very high carbon equivalent (hypereutectic) and slow cooling. It can consist of coarse primary graphite flakes, as well as small flakes. Sometimes, some flakes have sharp corners. Due to the high crystallization temperature and prolonged growth time, it forms coarse flakes with less branching. When the temperature drops to the eutectic temperature, a normal eutectic transformation occurs. The final result is normal eutectic graphite distributs between coarse graphite flakes. Therefore, type C graphite containis coarse, blocky graphite and type A graphite. Type C graphite can improve the thermal conductivity of cast iron and its resistance to thermal shock, but it has a significant impact on the mechanical properties of cast iron and should not be present in general structural castings. Excessive addition of inoculant can also cause localized silicon enrichment, which can also produce this type of graphite.

D and E Forms of Graphite in Cast Iron

Type D graphite forms between austenite dendrites when cast iron has a low carbon equivalent, a high cooling rate, a high degree of undercooling, and well-developed primary austenite dendrites. The graphite flakes are fine and non-directional. D-type graphite, also known as “undercooled graphite” or “interdendritic graphite,” is commonly found in thin-walled gray iron castings with a low carbon equivalent. In the absence of alloying elements, D-type graphite is often accompanied by ferrite. If the matrix structure is pearlite, the cast iron exhibits improved wear resistance and can achieve finer surface roughness after machining.

E-type graphite forms under conditions of low carbon equivalent and slow cooling rates. Due to slow cooling, austenite dendrites develop, and during eutectic transformation, the liquid phase is primarily located between the primary austenite dendrites. The resulting graphite flakes grow along the dendrites, exhibiting a certain degree of directionality. This significantly impacts the mechanical properties of the cast iron. Cast iron that may contain E-type graphite may also form D-type graphite if the cooling rate is high. To produce high-quality gray iron castings, the matrix should be entirely pearlite, the graphite should be type A, the graphite flakes evenly distributing within the metal matrix, and the pearlite should be fine and uniform. Type B and type D graphite should be minimized, and type C and type E graphite should be eliminated. To achieve this, effective inoculation treatment and controlled cooling rates are essential.