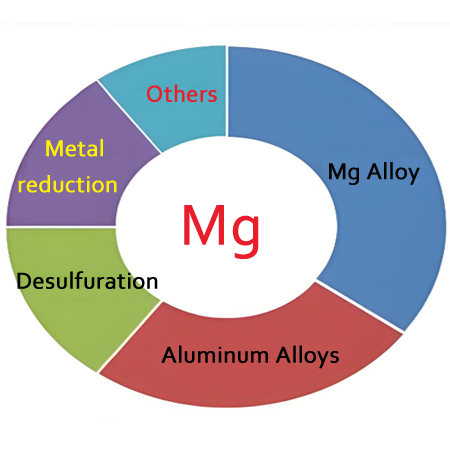

Magnesium alloy production dominates global magnesium consumption, accounting for about 50%, and global consumption in 2024 is about 500,000 tons. The applications of magnesium alloys includes automobile, aircraft and robot industries. Specifically in the automotive industry, North America and Europe uses 15-18 kg of magnesium per vehicle, China uses 10 kg. It is estimated that the global consumption of magnesium alloys for automobiles in 2024 is about 380,000 tons. As it accounting for about 70% of the total consumption. Mg alloy is and will kept being biggest the main consumption fields of magnesium. The consumption of magnesium alloys for 3C electronic products will account for about 20%. The consumption of magnesium alloys in other industries (such as aerospace, medical, robotics, eVTOL aircraft, construction, defense, etc.) will account for 10%.

Main Consumption Fields of Magnesium – Automobile

Among the many factors that affect the scale of magnesium alloy consumption, the rapid development of the new energy vehicle industry is particularly critical. With the urgent need for energy conservation and emission reduction worldwide, magnesium alloys have broad application prospects. In the field of new energy vehicles, it is especially notable. Study shows that by optimizing the composition and processing technology of magnesium alloys, their mechanical properties and corrosion resistance can be significantly improved to meet the needs of new energy vehicles for lightweight and high-performance materials.

In addition, policy-level support also provides strong guarantees for the application of magnesium alloys in the field of NEV. China has introduced a series of policy measures to encourage the development of new energy vehicles. These policies including support for the research and development and application of lightweight materials. These policies not only reduce the R&D costs of enterprises, but also provide support for their market promotion. In terms of market application, the application of magnesium alloys in new energy vehicles has achieved initial results.

Main Consumption Fields of Magnesium – Aluminum, Steel and Titanium

The magnesium products consumed in primary metallurgical fields such as aluminum alloys and steel are mainly Magnesium Ingot. The aluminum alloy addition field accounts for about 25% of global magnesium consumption. The global consumption of Al-alloys in 2024 is about 260,000 tons. The role of Silicon and Magnesium in Aluminum Alloys are very important. Thanks to the scale advantage of China’s NEV production accounting for 60% worldwidely, the demand for Al-alloys has strong support. However, the export growth of architectural aluminum materials is slowing down.

The incremental marginal effect of demand is gradually weakening. The steel desulfurization field accounts for 11% of global magnesium consumption, and the global consumption in 2024 is about 120,000 tons. The global crude steel output of 1.9 billion tons has laid a solid foundation for demand in this field. However, with the increasing popularity of short-process steelmaking, the magnesium consumption per ton of steel has dropped to 0.8 kg, resulting in a year-on-year decline of 18% in total demand.

The metal reduction field accounts for 8%, and the global consumption of last year is about 80,000 tons. Among them, due to the extensive use of full-process technology, China’s dependence on foreign purchases in sponge titanium production has dropped to about 10%. In addition, zirconium, uranium, and hafnium are also core application areas of magnesium reduction technology, but their consumption is much lower than titanium (titanium metal reduction accounts for 82%). With the continuous advancement of nuclear energy and aerospace technology, the demand for special metals such as thorium and beryllium is hopefully to gradually increase. However, in the short term, its role in driving magnesium consumption is still relatively limited.

Future Consumption Fields of Magnesium

Glolbal comprehensive analysis shows that main consumption fields of Magnesium will increase from 1.2 to 2.5 million tons in 2020-2030. The compound annual growth rate will be 11%. Among them, it is necessary to focus on the penetration rate of lightweight automobiles. According to estimates, the average amount of magnesium metal required for a car will increase from 5kg to more than 15kg. This will drive the consumption of magnesium metal in the transportation sector from 45% to 55%. The second largest sector is the demand for upgrading of aerospace, military industry and electronic products.

In addition, policy promotion also plays an important role in the consumption of magnesium ingot. A higher proportion of magnesium alloy recycling and utilization may also be put on agenda to promote the sustainable future of the magnesium industry in various economies. China, Europe and the United States may introduce new policy documents to replace steel with more magnesium to promote carbon peak and carbon neutrality.