The smelting process of silicon metal refers to the process of extracting silicon element from silica or its oxide through certain technical means. There are three theoretical methods for smelting industrial silicon: thermal decomposition, electrolysis and electrothermal reduction.

The so-called thermal decomposition method is a process in which the oxide is heated to a higher temperature to separate the oxygen element and the valuable element. For silica, due to the high affinity between silicon and oxygen, it needs above 2000°C or even higher to decompose. This is difficult to achieve in actual production, so the production of industrial silicon metal should not use this methods. The electrolysis method refers to the use of electrical energy to precipitate metals from solutions containing metal salts. The key to this method is to find a solution that can dissolve gold plant minerals. However, there are currently no reports of electrolytic production of industrial silicon in the world.

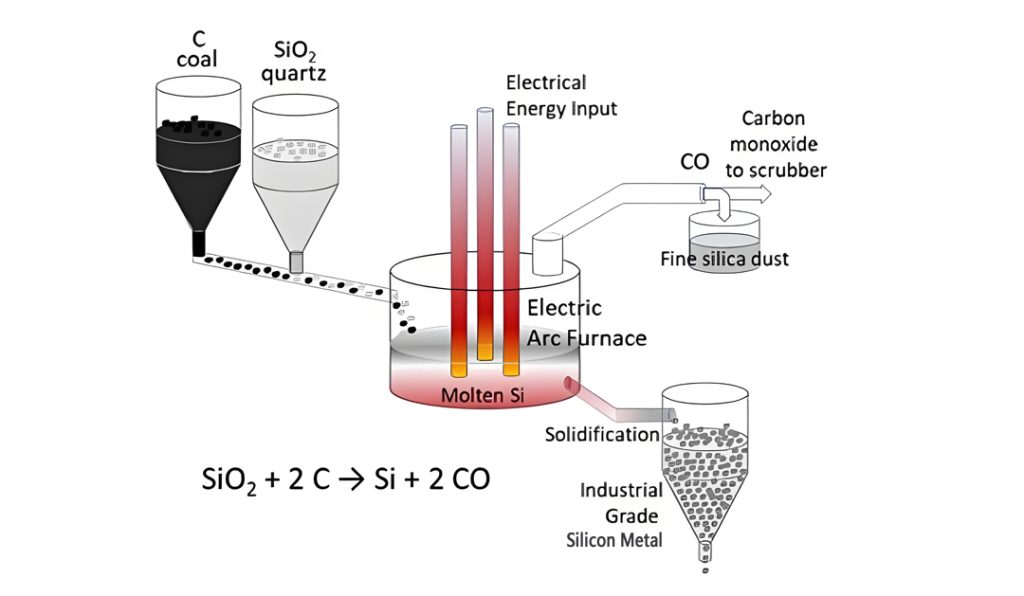

Electrothermal Reduction

Currently, electrothermal reduction is the most common method for producing industrial silicon in the world. This method mainly utilizes the difference in affinity between reducing agent, silicon and oxygen. And, it uses the reducing agent with strong affinity to oxygen to reduce the silicon with weak affinity to oxygen. However, due to the strong affinity between silicon and oxygen, it is difficult to reduce it at room temperature. It generally needs to be heated to high temperature before the reaction occurs. Since the required temperature is very high, conventional heating is difficult, so graphite electrodes are used for heating. So it is also called For electrothermal method.

When using electrothermal methods to produce silicon metal, choosing the appropriate reducing agent is key. Silica, which is the raw material for silicon metal production, usually contains about 98% SiO2. Reducers suitable for the smelting process of silicon metal include carbonaceous reducing agents, hydrogen-based reducing agents and some cheap metals. The electrothermal method is suitable for the production of most metallurgical grade silicon metal and chemical grade silicon metal. Common silicon metal 553, silicon metal 441, and Si 421, Si 331, etc. on the market all use this production method.

In fact, considering the economic cost, the only reducing agent suitable for the smelting process of silicon metal is carbonaceous reducing agent. Specifically, the available types include charcoal, petroleum coke, semi-petroleum coke, and some carbonaceous agricultural products such as rice husk, coconut shell, pine cone, etc. Silica and reducing agent are mixed according to a certain ratio and then heated to cause a reduction reaction. From this, we can get metallurgical grade silicon metal and most of the chemical grades silicon models.